GTS Keramik

Made in Germany

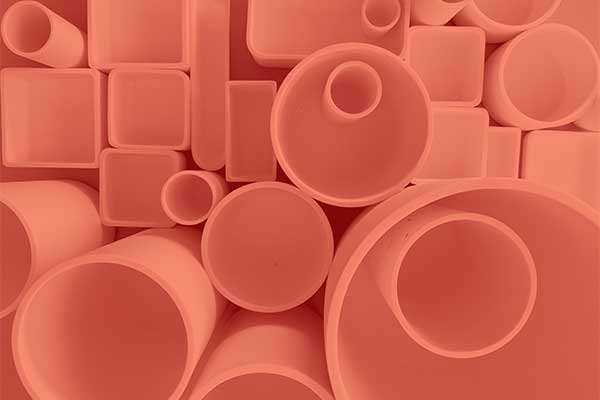

Products

As one of Germany’s leading manufacturers of industrial ceramics, GTS offers innovative solutions in the fields of special ceramics and wear technology. Our products in the areas of precision casting, jewellery casting, laboratory and medical technology are versatile. It is clear to us that the innovation and top quality of our products is founded on our many years of research and development. Our motto is “Always be one step ahead”! Discover the diversity of GTS and feel free to enquire about our products at no obligation.

Alumina dense

SPECIAL PROPERTIES

- high mechanical strength

- high wear resistance

- excellent antifriction properties

- high corrosion resistance

- high temperature resistance up to over 1700 °C

- good thermal conductivity

- high electrical insulation capacity

- Good to very good chemical resistance to: aluminium, beryllium, lead, chromium, iron, germanium, cobalt, copper, magnesium, manganese, nickel, silicon dioxide, hydrochloric acid (30%), vanadium, bismuth, tin, zinc

Alumina porous

SPECIAL PROPERTIES

- high mechanical strength

- high corrosion resistance

- temperature resistance up to over 1750 °C

- good thermal insulation

- high electrical insulation capacity

- Good to very good chemical resistance to: aluminium, beryllium, lead, chromium, iron, germanium, cobalt, copper, magnesium, manganese, nickel, silicon dioxide, hydrochloric acid (30%), vanadium, bismuth, tin, zinc

Aluminum titanate porous

SPECIAL PROPERTIES

- high mechanical strength

- high corrosion resistance

- high temperature resistance up to over 1600 °C

- Thermal insulation property

- Good to very good chemical resistance to: Aluminum

Fireclay (A3)

- Very high heat resistance up to 1200 °C

- Resistant to thermal shock

- Can be heated inductively

- Fireclay stores heat, preventing rapid solidification of the molten mass.

Magnesium oxide

SPECIAL PROPERTIES

Good to very good chemical resistance to: lead, beryllium, iron, copper, nickel, sodium, platinum, plutonium, uranium, bismuth, tin

Quartz

SPECIAL PROPERTIES

- low thermal expansion coefficient

- extremely high temperature change resistance

- high corrosion resistance to many molten metals

- high corrosion resistance in contact with many other chemical products

- Good to very good chemical resistance to: lead, gallium, germanium, copper, platinum, tin

Quartz with silicon nitride

SPECIAL PROPERTIES

- low thermal expansion coefficient

- extremely high temperature change resistance

- high corrosion resistance to many molten metals

- high corrosion resistance in contact with many other chemical products

- Good to very good chemical resistance to: platinum, silver

Zirconia high-density

SPECIAL PROPERTIES

- zirconia is a semiconductor

- high mechanical strength

- excellent wear resistance

- high fracture toughness

- high temperature resistance up to over 2000 °C

- low thermal conductivity

- high corrosion resistance

- Good to very good chemical resistance to: aluminium, beryllium, iron, cobalt, nickel, platinum, rhodium, hydrochloric acid (30%), bismuth, zirconium

Zirconia porous

SPECIAL PROPERTIES

- zirconia is a semiconductor

- high mechanical strength

- thermal insulation capacity at >1,700 °C

- high temperature resistance up to over 2000 °C

- low thermal conductivity

- high corrosion resistance

- Good to very good chemical resistance to: aluminium, beryllium, cobalt, nickel, platinum, bismuth